|

+Forging Part Design Class

.: a Symposium for Product Designers

and Mechanical Engineers :.

Course Duration:

16 hour workshop

Tuition: $1000 USD

Overview: The course and course material

is designed to provide a working knowledge of the metal forging industry.

The class is intended for those designers and engineers who are designing

forged parts using a parametric modeler. The bulk of time in this workshop

will be spent on the part design requirements imposed on the designer

by the forging process. Covered in this workshop are such as approach

to modeling forgings to learning techniques where designers take a weldments

and convert that assembly into a forged part. Read On.

Prerequisites: General knowledge of Pro/ENGINEER

another 3-dimensional CAD modeler helpful but not necessary.

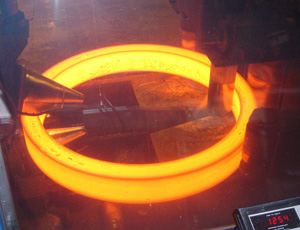

Forged

wheel. Forged

wheel.

Topics:

- Overview of the forging process complete with tooling, and outside machining

operations.

- Forging is process by which metal is heated and is shaped by plastic

deformation by suitably applying compressive force.

- Discuss the progression of a forging process.

- Open Die Drop hammer forging.

-- Impression-die drop-hammer forging.

- Press forging, upset forging, Automatic hot forging and roll forging.

- Powder mixes for compacting plus alloyed powder, composed of two or

more elements.

Forged brackets

forged crank

Discussions:

- Discuss the history of forming metals

- Discuss the forging process and it's specific history

- Advantages and Disadvantages with respect to cost and strength

- Discuss alloys with respect forging.

- Compare cold forging to hot forging & warm forging.

- In detail steps of the forging process

- Discuss strengths and weakness of outsourcing.

- Discuss basic design elements for forged part design. Holes, ribs, thin

wall features, bosses, nominal wall, and fill.

- Discuss general rules for forging and how material deforms so designers

can leverage flow for strength. impact flow

- Aircraft quality for high stress forged parts.

- Discuss auxiliary operations such as specific surface conditions or

specific shapes not obtained by the regular processing operation.

- Flow stress with respect to deformation

- Discuss heat treatment

- Discuss draft requirements with respect to material flow

- joining the Forging Industry Association.

- Discuss specification and purchasing quantities or tooling specific

to forging.

- Cost reduction and costing.

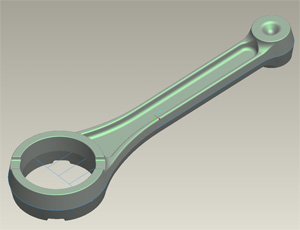

Harley Davidson forged Rod before machining features are added in Pro/ENGINEER.

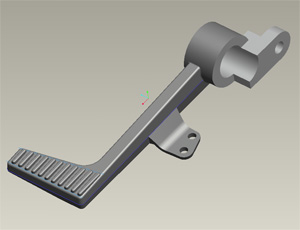

Completed Honda 600rr forged brake lever with 7 degrees draft. Screen

shot is from Pro/ENGINEER.

Participants will watch instructor construct geometry and will be allowed

to build the geometry with instructor assistance.

Pro/ENGINEER specific: (watch instructor

perform in realtime)

- Watching your instructor, realize draft in it's many forms complete

with examples of split draft etc.

- Learn to use a bit of surfacing, discuss it's usefulness with forged

part design.

- Learn to convert weled assemblies complete with complex draft to a forged

process.

- Discuss making parts ready for the forging process that others created

i.e. technique, draft, strike direction.

- Techniques for converting multiple Pro/E parts from a weldments into

a cheaper stronger forged part.

- Discuss tips tricks and techniques for starting and completing forging

parts using Pro/ENGINEER.

- Learn to use parameters, relations and underlying curve geometry to

drive Pro/E geometry with respect to Forged parts.

- Discuss ribs and the addition of gage geometry for aligning for the

CNC matching process forge part.

- Learn to use utilize Draft check analyses tools correctly

- Discuss chrome applications and other plating, painting or powder coating

processes.

- Techniques for managing the Pro/E machining features.

- Techniques for mounting your forged part to your CNC machine

- Prints, specification and notes for forging detail drawings.

These are HTML tutorials available for participants who will be able

to utilize after this workshop.

Tutorials : (watch instructor perform

in realtime these models before participatns create the models)

Motorcycle Brake Lever

Pivot Bracket

Harley Rod

Motorcycle Kickstand

Sample

forged parts and tools. Sample

forged parts and tools.

Compare:

- Compare metal injection molding or powder injection molding to forging

- Forging process and product to Die casting process

- Die casting vs. forging process with respect to cost and qty.

hand

forging a horse shoe hand

forging a horse shoe

Hydraulic

drop-hammer Hydraulic

drop-hammer

a

typical forging before a final trimming blow event a

typical forging before a final trimming blow event

This raw aluminum piston forging shows just how “raw” a piston

is before it’s gone through several machine operations to complete

the product

The piston on the right is a forged piston with a separate coat of powder

that is used as a bonding agent to seal the aluminum from absorbing water.

Example of one of seven Pro/E projects where techniques for complex draft

for forged parts make Pro/E easier.

|