|

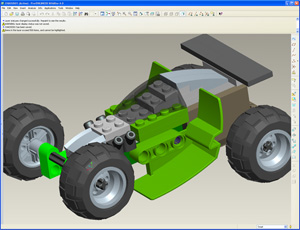

+Week Long Manufacturing Part Design Class :.

Combines Plastics, Die Casting and Forging into a one week intensive.

Course Duration:

40 hour workshop

Tuition: $2500 USD

Overview: The course includes each of

design engine's plastics

class,

die cast class and forging

class into this forty hour one week

intensive. Refer to those specific web pages for precise course material.

This class is not for Pro/ENGINEER beginners. Training material for this

one week design intensive has been designed to provide a working knowledge

of both the molding and forming industry and includes more than half of

the hours utilizing modeling techniques in Pro/ENGINEER. This class does

not cover the actual writing of CNC code for numeric controls or Sheet

metal as those are separate design engine classes.

Take ten minutes to review this course overview.

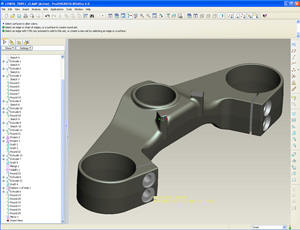

Triple clamp Pro/ENGINEER model converted to the Diecast process from

a machined from billet model.

Triple clamp Pro/ENGINEER model converted to the Diecast process from

a machined from billet model.

Prerequisites: Significant knowledge

of Pro/ENGINEER or another parametric 3-dimensional CAD modeler.

Die Casting short list of Topics:

- The process, die cast molds, tooling, processing factors, Nominal

Walls, - Radii and draft angles, Ribs, Weldlines, stress, cooling metals,

bosses, undercuts.

- Also snap fit, FEA, Design recommendations, overview of flow mold

analysis software.

for complete list of course material see the design

engine

die cast class.

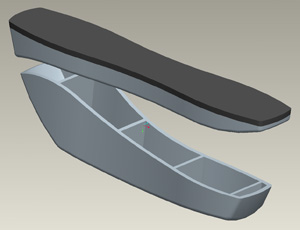

A Harley Davidson Die Cast stylized part showing example of a chrome A-side

surface.

Short List of Die Cast Discussions:

- Discuss cooling time as related to thick sections of aluminum. Discuss

internal voids and fundamentals of other problems that occur from improper

piece part design.

- Discuss using parametric modelers in general and discuss examples where

using variables with a parametric modeler can save problems in the future

complete with in class examples.

For a more complete list of course material of this class refer to

the design engine

die cast class web pages.

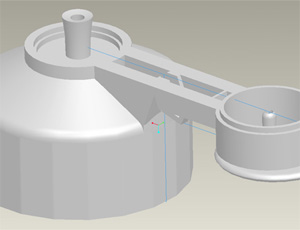

Die Cast Aluminum Pro/E model. In this Pro/ENGINEER tutorial the user

will create ribs that are offset from the parting line instead of what

is shown. This is also a Copy Geometry tutorial all a part of this die

cast part design class.

Pro/ENGINEER specific:

- Discuss draft in it's many forms complete with examples of split draft

etc.

- Learn to use surfacing and discuss it's usefulness with die cast part

design.

- Learn to use top down design with examples in Pro/ENGINEER.

- Adding draft to parts that currently have no draft.

For a more complete list of die cast training material of this class

refer to the design engine

die cast class web pages.

There is a great deal of HTML course material students take back with

them from this workshop.

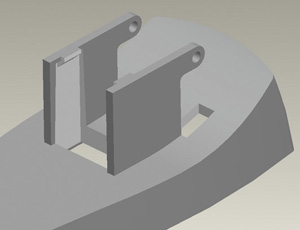

Pro/ENGINEER tutorial that shares modeling technique for creating

shut off geometry.

Die Cast parts from a dual cavity mold. Notice the flash, runners and

gate.

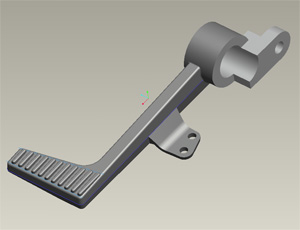

Die Cast Pro/ENGINEER model of a motorcycle foot peg utilizes unique modeling

technique.

Plastic Part Design Topics:

- Product Development & Prototype

- Mold Filling, Gating & Weld Lines

- Mechanical Behavior of Polymers

- Shrinkage, Warpage & Part Ejection

For a more complete list of plastics course material of this class

refer to the design engine

plastics

class web pages.

Plastics Discussions:

- Discuss basic design elements in plastic part design. Holes, ribs,

thin wall features, bosses, nominal wall, and fill.

Discuss general rules for hollow boss design and discuss best practices.

Learn about thin steel or thin blade areas and discuss ways to avoid.

- Designing undercuts and discuss advantages and disadvantages as relative

to costs

- General disclaimers on drawings such as "brake all sharp corners".

In this exercise participants will add draft and prepare any number

of parts for the plastic injection molding process.

Discussions with respect to Pro/ENGINEER:

- Light surfacing and its use with plastic part design.

Discuss top down design with examples.

- Adding draft to parts that currently have no draft.

Discuss making parts moldable that others created.

- Tips tricks and techniques for starting and completing plastic parts

using Pro/ENGINEER.

For a more complete list of course material of this portion of the

manufacturing week long class refer to the design engine

plastics

class

web pages.

After

discussing live hinges in some detail participants in this course will

look at suggestions for specific materials and modify or create a live

hinge that will meet spec sheets supplied. After

discussing live hinges in some detail participants in this course will

look at suggestions for specific materials and modify or create a live

hinge that will meet spec sheets supplied.

Forging Topics:

- Overview of the forging process complete with tooling, and outside

machining operations.

- Forging is process by which metal is heated and is shaped by plastic

deformation by suitably applying compressive force.

- Discuss the progression of a forging process.

- Open Die Drop hammer forging.

Discussions:

- Discuss alloys with respect forging.

- Compare cold forging to hot forging & warm forging.

- In detail steps of the forging process

- Discuss strengths and weakness of outsourcing.

For a more complete listing of course material see the design engine

forging

class overview pages.

-

Short List of Plastic Tutorials :

(watch instructor perform in realtime these models before participants

create the models)

Motorcycle Brake Lever

Pivot Bracket

Harley Rod

Motorcycle Kickstand

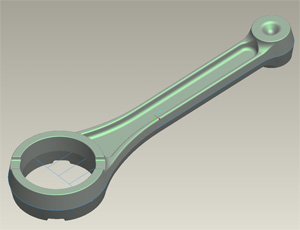

Harley Davidson forged Rod before machining features are added in Pro/ENGINEER.

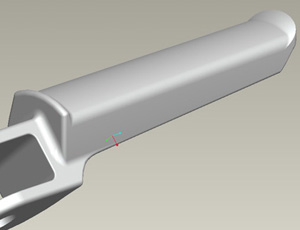

Completed Honda 600rr forged brake lever with 7 degrees draft. Screen

shot is from Pro/ENGINEER.

Pro/ENGINEER specific:

- Discuss top down design with examples on forged parts.

- Discuss adding draft to parts that currently have no draft.

- -Discuss making parts ready for the forging process that others created

i.e. technique, draft, strike direction.

For more complete course description refer to the design engine

forging

class class web pages.

The piston on the right is a forged piston with a separate coat of powder

that is used as a bonding agent to seal the aluminum from absorbing

water.

|