|

+Pro/SHEETMETAL Level 2 Training (Wildfire 3.0

& Wildfire 4.0 available)

Course Duration:

16 Hours

Tuition: $1200 US

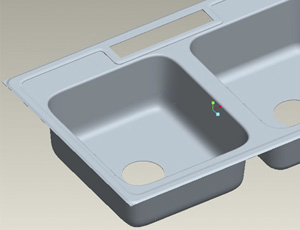

Overview: This is an advanced Sheet

metal course. Students will be trained to work on items such as small

battery contacts, aircraft mounting brackets, electronics enclosures,

larger stove/oven components, or auto panels to name a few.

Prerequisites: Prior experience with

Pro/SHEETMETAL and a willingness to learn.

Topics:

- Set up Pro/SHEETMETAL for team design efforts

- Bend Allowance and Developed Length

- Punch and Die reference parts

- Sheet Metal Bend Tables

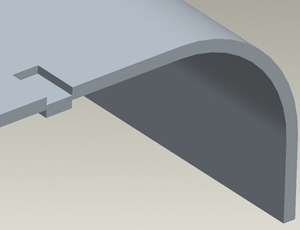

- Transition Bends

- Xsec-Driven Bends and Unbends

- Deformation Areas

Exercise:

- Layout and develop oven and stove component.

- Create complex beryllium copper battery contact with bend on top of

form feature.

- use bend table to control

- Use automatic Ordinate Dimensions on sheet metal component in drawings.

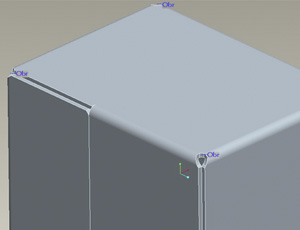

- Design sheet metal parts defining the volume and support structures

for the components of an assembly.

Discussion:

- Discuss differences between Notch forms and Punch forms.

- Transition Bends

- Sheet Metal Design Approach

- Discuss 2001 and Wildfire iconography.

- Discuss K and Y factors and how to modify them for specific tooling

or prototyping

- Discuss stretching due to deformation areas

- Create Bend Order tables that specify the order, bend radius and bend

angle used for manufacturing.

- Calculate the developed length of material needed. Pro/SHEETMETAL

accounts for bends of different radii and material thickness.

Project:

Calculate the developed length of material needed. Pro/SHEETMETAL accounts

for bends of different radii and material thickness.

Several Brackets, Deep drawn form and combination.

Curriculum can be combined with Pro/SURFACE tools for automobile sheet

metal functions or for smaller battery contacts.

Convert IGES file with inconsistent wall thickness and punch geometry

into a Pro/SHEETMETAL part ready for production.

Learn to design sheet metal geometry with form features

one tutorial for converting a solid into sheet metal complete with rips

and obrounds

punch geometry

|